ISSN: 0973-7510

E-ISSN: 2581-690X

Lactic acid bacteria, particularly Lactobacillus bulgaricus and Streptococcus thermophilus, are widely employed in yogurt production to ferment milk, contributing to its characteristic taste, aroma, and texture. Powdered yogurt offers practical advantages for consumers due to its prolonged shelf life. Recently, natural additives such as green tea have been incorporated into yogurt formulations to enhance their nutritional value. For green tea-enriched powdered yogurt, determining the optimal temperature for reconstitution is crucial to ensure product quality. This study investigated the effect of different solvent temperatures on the total LAB population, visual color attributes, and reconstitution solubility. A completely randomized design (CRD) was employed, comprising four temperature treatments (30 °C, 45 °C, 60 °C, and 75 °C) with three replications each. The results indicated that rehydration temperature did not significantly affect total lactic acid bacteria count, lactic acid bacteria viability cost-efficiency, or color parameters (L* for lightness, a* for green-red, and b* for yellow-blue). However, solubility was significantly higher when reconstitution was performed at 75 °C. These findings suggest that 75 °C is the most effective solvent temperature for dissolving green tea yogurt powder.

Yogurt Powder, Green Tea, Solvent Temperature, Lactic Acid Bacteria, Physical Quality

Yogurt typically contains lactic acid bacteria, including Streptococcus thermophilus and Lactobacillus bulgaricus. Through the fermentation of milk components by these microorganisms, yogurt develops its characteristic flavor, aroma, and texture. Yogurt is most commonly available in liquid to semi-solid form. This limited texture requires specific storage conditions, namely refrigeration at approximately 4 °C. Such requirements make the product less convenient for consumers to transport. Products with a liquid texture are also more susceptible to damage during transportation due to shocks and movement during transport. To overcome these limitations, liquid yogurt can be processed into powder.1

Yogurt powder offers ease of use, an extended shelf life, and greater practicality for consumers. It is typically reconstituted just before consumption. Consumers simply add water and stir until fully dissolved. In the future, reconstituted yogurt could be served conveniently to consumers, providing both practicality and longer storage stability. Furthermore, reconstituted yogurt products could represent high-quality and commercially valuable products for the food industry and consumers. Therefore, reconstituted yogurt has the potential to become a promising business opportunity.2

Yogurt is currently being developed with the inclusion of botanical ingredients, among which green tea is undoubtedly one. Green tea contains polyphenols, which are well known for their antioxidant properties. According to Sulistiorini et.al.,3 green tea leaves (Camellia sinensis) have been shown to contain active compounds that are beneficial for health. Phenolics are one of the components in green tea leaves that can act as antioxidants. In addition, green tea can inhibit several pathogenic bacteria, but it does not inhibit probiotic bacteria.4 Moreover, green tea extract contains selenium compounds, which increase the activity of one of the lactic acid bacteria in yogurt, namely Streptococcus thermophilus.5 Therefore, the incorporation of green tea into powdered yogurt formulations can improve the final quality of the yogurt product.

Green tea powdered yogurt requires an appropriate solvent temperature when reconstituting, due to the presence of Lactic acid bacteria in the product, according to Najgebauer.6 The amount of Lactic acid bacteria contained in yogurt is one of the key factors determining whether this product can be classified as a functional food. Furthermore, the dissolution temperature during reconstitution plays a significant role in the solubility of the components in green tea powdered yogurt. Protein is also an important nutritional component in food. Proteins in food possess a wide range of functional properties, such as solubility, emulsification capacity, foam and gel formation, water and curd retention, and flavor binding. The concentration of protein in a food product can significantly influence these characteristics, ultimately affecting the texture, stability, and sensory qualities of the final product across various foodstuffs.7 Solubility in water is measured to determine the presence of bonds in polymers, as well as the degree or regularity of these bonds, and to estimate the stability of bioplastics to the influence of water.8 In addition, the dissolution temperature during reconstitution also plays an important role in the color appearance of the final yogurt product. At certain temperatures, chlorophyll is released and changes the color of the yogurt product upon reconstitution.9 The combination of green tea chlorophyll color and the nutritional components of milk (especially protein) will affect the color attributes of the final product. This research aims to determine the effect of solvent temperature on the solubility, color attributes, and total lactic acid bacteria count in reconstituted green tea yogurt. The purpose of this study is to provide scientific data on the appropriate solvent temperature for optimizing lactic acid bacteria count, color, and solubility in reconstituted green tea yogurt.

Research Preparation

The materials used in this study were starter cultures yogurt (L. bulgaricus and S. thermophilus), green tea extract, skim milk, liquid milk, distilled water, granulated sugar, nutrient agar, and others.

Equipment

The equipment used in this research included test tubes, sample bottles, Erlenmeyer flasks, autoclave, measuring cups, stirrers, a clean bench, micropipettes, blue tips, white tips, Bunsen burner, tube rack, analytical scales, freeze dryer, freezer, beaker glasses, incubator, vortex mixer, pan, thermometer, and others.

Sample preparation

Yogurt starter preparation

Starter culture yogurt (L. bulgaricus and S. thermophilus) was used as a starter source. Microorganism growth media (mother and starter cultures) were prepared from reconstituted 5:10% (weight/volume) skim milk. The media was first sterilized at 105 °C for 5 minutes and then cooled. Next, the cooled sterile medium was inoculated with commercial yogurt at 3% (volume/volume). Culture activation was carried out twice before using the yogurt starter (adapted from the Donmez et al.10 The mother or starter medium was harvested after incubation at 44-45 °C for 14 hours. The starter was then ready to be used to make green tea yogurt.

Green tea extraction

Green tea extract was prepared from dried green tea, which was extracted with hot water and then filtered. The green tea used was commercially purchased dried green tea. The green tea extract was left to stand for 3 minutes at a water temperature of 90 °C. The ratio of green tea to water used in making the extract was 1:20 (weight/volume).11

Making Tea powdered Yogurt

Green tea yogurt was prepared using the following ingredients: 10% (weight/volume) skim milk, 5% (volume/volume) sugar, and 20% (weight/volume) green tea extract. All ingredients were homogenized and bottled. Next, the bottles were sterilized at 105 °C for 5 minutes and cooled to around 37 °C. After cooling, the medium in the bottles was inoculated at 3% (volume/volume) with the yogurt starter (previously prepared), and the green tea yogurt was harvested after incubation at 44-45 °C for 14 hours. The green tea yogurt was then dried in an oven at 50 °C until it reached a powdery texture. The powdered yogurt was stored for 1 day before being reconstituted with warm water according to the treatment temperatures: 30 °C, 45 °C, 60 °C, and 75 °C, with a ratio of 1:3 (powdered yogurt:water). The reconstituted yogurt was then evaluated for quality parameters (L*, a*, and b* values), solubility, and lactic acid bacteria count.

Measured parameters

Lactic acid bacteria

Counting the total colonies of lactic acid bacteria was carried out using the pour plate method. Samples were serially diluted from 10-1 to 10-7. Dilution was performed by preparing 7 test tubes, each containing 9 mL of sterile distilled water. One milliliter of yogurt was added to the first tube, producing a 10-1 dilution. Subsequently, 1 mL from the 10-1 dilution tube was transferred to the second tube, producing a 10-2 dilution, and so on until a 10-7 dilution was obtained. Next, 1 mL of each sample was placed into a Petri dish. Nutrient agar (NA) medium supplemented with 10% (weight/volume) liquid milk (based on the NA volume) was sterilized and then cooled. The cooled sterile medium was poured into the Petri dishes containing the previously diluted bacteria. The plates were gently swirled to homogenize the mixture and left to solidify. Petri dishes were incubated at 44-45 °C for 24-48 hours, after which the total LAB colonies were counted. The formula for calculating the number of bacterial colonies is as follows:

Total lactic acid Bacteria (log CFU/mL = Number of colonies × dilution factor / Volume Plated (ml)

Solubility test

The solubility test of reconstituted green tea yogurt was conducted using a manual stirring method that had been previously standardized. The solubility of a compound depends on the physical and chemical properties of both the solute and solvent, as well as on factors such as temperature, pressure, solution pH, and-on a smaller scale-the distribution of the solute.12 Standardization was carried out by stirring a solution in a small glass with a teaspoon, counting the number of stirs made in one minute to determine the average stirring rate per minute. The stirring technique was performed as if preparing a beverage for serving. The ratio of powder to water in this solubility test was 1:3 (weight/volume), meaning that 3 mL of water was used to dissolve 1 g of powder.13 The sample was stirred until completely dissolved at a standardized stirring speed of 130 stirs per minute. A powder was considered dissolved when a homogeneous dispersion was achieved in terms of both color and texture. A total of 12 solubility tests were conducted, each in triplicate. The dissolution times for each sample were then compared to identify those with the best rehydration quality.14

Coloration Value ( L*, a* and b*)

Color measurement was performed using a digital color meter (T135 model). The readings from the device are represented by L*, a*, and b* values, which are defined as follows: L* = 0 (black) to 100 (white), a* = -60 (green) to +60 (red), and b* = -60 (blue) to +60 (yellow). The device was calibrated prior to use to ensure more accurate results.15 Green tea yogurt samples were placed on white paper. The T135 device was positioned perpendicularly above the sample and then activated to take the reading. The value displayed on the device represented the color measurement of the tested sample.

Data analysis

The research data were analyzed using Analysis of Variance (ANOVA) based on a Completely Randomized Design (CRD) with a 3 × 3 factorial arrangement. Statistical analysis was conducted using SPSS software (version 16.0).

Lactic acid bacteria in green tea powdered Yogurt

Lactic acid bacteria are a group of Gram-positive bacteria that do not form spores and are able to ferment carbohydrates, producing lactic acid as the final metabolite. The total count of lactic acid bacteria colonies in powdered green tea yogurt reconstituted with different solvent temperatures is presented in Figure 1.

Figure 1. Lactic acid bacteria (CFU/ml) powdered green tea yogurt reconstituted with different solvent temperatures

Based on the analysis of variance, the use of different solvent temperatures had no significant effect (p > 0.05) on the lactic acid bacteria in yogurt. This suggests that, in general, solvent temperature only caused a slight decrease in the lactic acid bacteria. However, statistically, the reduction in the lactic acid bacteria among the different solvent temperature treatments in this study was not significant.

This condition indicates that using solvent temperatures between 30 °C and 75 °C during the reconstitution of green tea yogurt does not affect the growth of lactic acid bacteria in the product. The lactic acid bacteria of green tea yogurt reconstituted at temperatures between 30 °C and 75 °C ranged from approximately 7.2 log CFU/mL (≈ 107 CFU/mL) to 8.2 log CFU/mL (≈ 108 CFU/mL). The lactic acid bacteria observed in this study was still within the range required by SNI (2009), namely 107 (7 log CFU/mL).16

In a study on yogurt samples supplemented with various concentrations of mango fruit extract, the lactic acid bacteria obtained did not show a significant effect, but the average result indicated an increase in lactic acid bacteria. This is because the addition of mango fruit extract provides additional nutrients for lactic acid bacteria growth by utilizing the glucose content found in mango fruit. The resistance of lactic acid bacteria to solvent temperature during the reconstitution of green tea yogurt is related to the characteristics of yogurt bacteria, which are generally thermophilic and thermoduric.17-19 At low heating temperatures, LAB can survive because of their thermophilic nature. Lactobacillus bulgaricus, for instance, is a Gram-positive bacterium that is thermoduric, unable to grow at 10 °C, but grows optimally at 50-55 °C.20 Another factor that affects the quality of yogurt is the incubation time. Longer incubation periods result in greater lactic acid production, thereby lowering the pH.

In addition, the solvent temperature used during reconstitution may also influence protein solubility and the stability of bioactive compounds from green tea extract. Studies have shown that higher temperatures can enhance protein dispersion, but excessively high temperatures may degrade phenolic compounds and catechins, which are the main antioxidants in green tea.21,22 This balance between microbial survival and bioactive compound stability is important in determining the overall quality of powdered yogurt.

Furthermore, the stability of lactic acid bacteria during reconstitution indicates that these microorganisms are relatively tolerant to temperature changes in the range of 30-75 °C. This tolerance is supported by previous findings that lactic acid bacteria, particularly Streptococcus thermophilus and Lactobacillus bulgaricus, are able to maintain viability in moderate heat conditions, making them suitable for use in dried and rehydrated dairy products.23

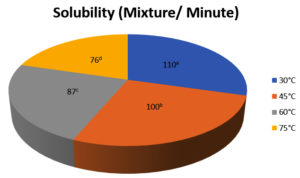

Solubility of powdered green tea Yogurt

Solubility is the ability of a substance to dissolve in another substance with similar polarity properties. Solubility testing of reconstituted green tea yogurt was conducted using a previously standardized manual stirring method. According to Mucheru et al.,21 the brewing method is particularly effective in maximizing antioxidant compounds. This technique helps maintain the quality of the desired compounds and prevents degradation of tea’s chemical constituents. The manual stirring method represents the rate at which a substance dissolves in a solvent; the greater the number of stirs per minute, the higher the solubility potential of the substance.22 Solubility can also influence the viscosity of reconstituted green tea yogurt when prepared at different solvent temperatures. The solubility results of powdered green tea yogurt at various solvent temperatures are presented in Figure 2.

Figure 2. Average solubility (stir/minute) of reconstituted green tea yogurt at different solvent Temperatures

Note: Means with different superscripts indicate a highly significant effect (p < 0.01)

Based on the analysis of variance, the use of different solvent temperatures had a highly significant effect (p < 0.01) on the solubility (stirs/minute) of reconstituted green tea yogurt. Duncan’s post-hoc test confirmed that solubility increased significantly (p < 0.01) as the dissolution temperature rose. This indicates that the higher the solvent temperature during reconstitution, the faster the dissolution rate, meaning that the probability of powdered products dispersing effectively improves as the water temperature increases.

Solvent temperature strongly influences the solubility of a material. The organic components in a material have different solvent temperature thresholds at which they dissolve optimally. Increasing the solvent temperature to 75 °C during the reconstitution of powdered green tea yogurt resulted in the highest solubility, namely 76 stirs/minute.

This finding is consistent with Wang et al.,23 who reported that solubility decreases with excessive heating, since most solid substances absorb heat during dissolution. Likewise,14 people researched powdered beverages based on broccoli with maltodextrin and found solubility values ranging from 122-130 stirs/second, where the best solubility corresponded to the lowest number of stirs (122 stirs/second).

Color Characteristics (L*, a* and b*) of Powdered Green Tea Yogurt**

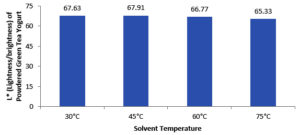

L value (Lightness) of Powdered Green Tea Yogurt

The L value (lightness/brightness) describes the range of 0 = black to 100 = white. Changes in the L value of powdered green tea yogurt during reconstitution can be observed in Figure 3.

Figure 3. Average L* color value (lightness/brightness) of powdered green tea yogurt reconstituted at different solvent temperatures

The range of L* values in this study was 65.33-67.91. Based on the results of the analysis of variance, the use of different solvent temperatures did not significantly affect the L (brightness) value of reconstituted green tea yogurt.* This indicates that employing a range of solvent temperatures does not change the L* color value of yogurt.

The L* value obtained in this study illustrates that light transmission can still penetrate the color components in the green tea yogurt product. The color of green tea yogurt is a combination of the whitish color derived from yogurt components and the green hue from chlorophyll compounds in green tea. This finding is supported by Zhou et al.,24 who stated that the white color of the main raw material, milk, is produced by casein. Casein is yellowish-white in its pure state, snow-like, odorless, and tasteless, allowing it to still be penetrated by light.

Based on Figure 3, the L* (brightness) values of reconstituted green tea yogurt ranged from 65.33 to 67.91. These values are lower than those reported by Amanto et al.25 for casein products, which ranged from 78.12 to 89.53. A higher L* value indicates greater brightness or whiteness in casein-containing milk. In the present study, the L* values decreased as the solvent temperature increased.

According to Rohman et al.,26 the brightness value decreases with higher concentrations of black rice extract, producing a darker product with a more intense purplish color. A similar trend was observed in this study, where increasing solvent temperature likely altered the solubility of color compounds in green tea yogurt, leading to reduced brightness.

Chlorophyll in green tea is known to be hydrophilic and relatively active at elevated temperatures. Hydrophilic compounds can bind with water due to their polar structure and generally form oil-in-water emulsions. As stated by Jeong et al.,27 chlorophyll compounds are highly sensitive to light, temperature, pH, and oxygen, and remain relatively stable at temperatures up to 100 °C. These conditions cause the components of green tea yogurt to bind more tightly, which is believed to contribute to the observed decrease in brightness values.

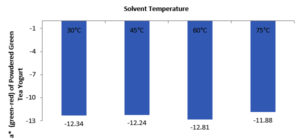

Color value a (Greenish) of Powdered Green Tea Yogurt

The a* color value represents the chromatic range from -60 = green to +60 = red. Changes in the a* color value of reconstituted powdered green tea yogurt at different solvent temperatures are presented in Figure 4.

Figure 4. Average a* (green-red) color value of powdered green tea yogurt reconstituted at different solvent temperatures

The range of a* values in this study was -11.88 to -12.34, indicating that the color formed in the product was greenish. Based on the analysis of variance, the use of different solvent temperatures did not have a significant effect on the greenish color (a) of reconstituted green tea yogurt. This suggests that solvent temperature variation does not alter the a* color value of green tea yogurt. The green color observed in green tea yogurt originates from chlorophyll.

Chlorophyll is a green pigment found in chloroplasts. In higher plants, chloroplasts are mainly located in the palisade parenchyma and spongy parenchyma of leaves. Within chloroplasts, the primary pigment is chlorophyll, along with carotenoids and xanthophylls, which are located in the thylakoid membranes. According to Kusmiyati et al.,28 the pigment content in green tea leaves is approximately 0.019%. One of the determining factors for the quality of green tea is its color, in which chlorophyll plays a major role in contributing to the green appearance

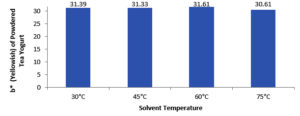

Color Value b* (Yellowish) of Powdered Green Tea Yogurt*

The b* (yellow) color value represents the scale ranging from -60 = blue to +60 = yellow. Changes in the b* color value of powdered green tea yogurt upon reconstitution can be observed in Figure 5.

Figure 5. Average b* color value (yellowish) of green tea yogurt reconstituted with different solvent temperatures*

The range of b* values in this study was 30.61-31.61, indicating that the color formed in the product was yellowish. Based on the analysis of variance, the use of different solvent temperatures did not significantly affect the b* (yellowish) color value of green tea yogurt when reconstituted, which is consistent with the findings of Jakubowska et al.29 Sensorily, plain yogurt is typically described as light white, bright white, or yellowish white. This appearance is caused by light reflection produced by the colloidal dispersion of casein and calcium phosphate. The yellowish color of yogurt originates from two main pigments in milk: carotene, which is found in milk fat, and riboflavin, which is present in milk whey. Therefore, the use of different solvent temperatures does not alter the yellowish (b*) color value of green tea yogurt.

The yellowish color observed in this study is thought to be derived from the milk fat content of the yogurt formulation. A lower milk fat content results in reduced levels of β-carotene in milk, thereby influencing color formation. According to Ramaiyuli et al.30 In addition, the presence of green tea powder contributes chlorophyll pigments, which may slightly mask or modify the yellowish appearance, depending on concentration and interaction with milk components. This is in line with Walstra,31 who reported that the addition of chlorophyll-containing extracts in dairy products can shift the b* values toward lower intensity, reducing the dominance of yellowish tones.

When compared with previous studies on dairy products fortified with plant-based pigments, such as black rice extract or matcha powder, the b* values obtained in this study are relatively moderate. For instance, Nguyen and Hwang32 found that increasing concentrations of plant pigments reduced the brightness (L*) and shifted both a* and b* values toward darker or less intense tones. In contrast, the stable b* values observed in this study indicate that the incorporation of green tea powder into yogurt powder maintained the typical yellowish characteristics of milk, suggesting that chlorophyll and other polyphenolic compounds did not strongly interfere with the yellow pigments of milk. This finding highlights the stability of color parameters in reconstituted green tea yogurt, even under varying solvent temperatures.

Walstra31 further stated that the white color of milk results from the dispersion and reflection of light by fat globules and colloidal particles of casein and calcium phosphate. The yellowish hue, on the other hand, originates from fat-soluble pigments, primarily carotene, which is naturally present in milk.

The variation of solvent temperature during the reconstitution of green tea yogurt exerts minimal effects on the total count of lactic acid bacteria and on the color parameters L* (lightness), a* (greenness), and b* (yellowness). Nevertheless, increasing the solvent temperature up to 75 °C significantly improves the solubility of the reconstituted product. This finding indicates that while the functional and sensory quality of green tea yogurt powder remains relatively stable across different solvent temperatures, the efficiency of rehydration can be enhanced under higher thermal conditions. Such results provide valuable insights for optimizing the preparation process of powdered yogurt-based products, ensuring both microbial stability and desirable physicochemical properties during reconstitution.

ACKNOWLEDGMENTS

The authors would like to thank the Rectorate of Hasanuddin University, Faculty of Animal Husbandry, Hasanuddin University, Milk Processing Biotechnology Laboratory, for the support and infrastructure provided.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

AUTHORS’ CONTRIBUTION

FM conceptualized the study. DMP and AA conducted the experiments. DMP and HB performed the calculations and statistical analysis. DMP, FM, and HH wrote and revised the manuscript. All authors read and approved the final manuscript for publication.

FUNDING

None.

DATA AVAILABILITY

All datasets generated or analyzed during this study are included in the manuscript.

ETHICS STATEMENT

This article does not contain any studies on human participants or animals performed by any of the authors.

- Rahmi I, Al Faizah BN, Dawama NF, et al. Probiotic-green tea yoghurt on improving testicular histology of high-fat and fructose diet mice. Jurnal Kefarmasian Indonesia. 2024;14 (2):147-156.

- Zjahra VN, Try MR, Arif F. Extraction of phenolic compounds in green tea leaves (Camellia sinensis), Akta Kimindo. 2022;7(1):69-76.

Crossref - Sulistiorini I, Nur RH, Yayan R, Deni F, Nina K, Alya NL. Formulation and evaluation of oatmeal and yogurt body scrub cream preparation as active substances. Medimuh: Muhammadiyah Health Journal. 2023;4(1):59-68.

Crossref - Wilna I, Aji J, Muhammad ZF. Comparison of proximate, antioxidant, and anthocyanin content of various food products with the addition of natural butterfly pea flower dye. Journal of Halal Food Science. 2023;5(2):163-174.

Crossref - Rahmani F, Gandomi H, Noori N, Faraki A, Farzaneh M. Microbial, physiochemical and functional properties of probiotic yogurt containing Lactobacillus acidophilus and Bifidobacterium bifidum enriched by green tea aqueous extract. Food Sci Nutr.;9(10):5536-5545.

Crossref - Najgebauer L, D, Zmudziński D, Ptaszek A, Socha R. Textural properties of yogurts with green tea and Pu-erh tea additive. Int J Food Sci Technol. 2014;49(4):1149-1158.

Crossref - Suci RD, Nabila NC, Ratri AN, Tita DNN, Nurul HF, Mohammad K. Preparation and characterization of water solubility and biodegradability of bioplastics from rice bran–corn mixtures. In Proceedings of the National Research Seminar, Institute for Research and Community Service, Muhammadiyah Jakarta University, 2020;3(7):2745-6080. https://jurnal.umj.ac.id/index.php/semnaslit/article/view/7796/0

- Maharani S, Rahayu A, Azizah DN, Rahayu DL. Comparison of tea extract addition on the chemical characteristics of Caspian Sea yogurt. Scientific Journal of Animal Husbandry Animal Products. 2019;3(2):138-149.

Crossref - Andi MNF, Ratmawati M, Fatma M. In vitro test of kefir mask in combination with “Black Powder.” Advances in Environmental Biology. 2019;13(2):13-16.

Crossref - Donmez O, Mogol BA, Gokmen V. Syneresis and rheological behaviors of set yogurt containing green tea and green coffee powders. J Dairy Sci. 2016;100(2)901-907.

Crossref - Suzanna T, Netty K, Indah K. Effect of sugars and concentration of green tea extract on physicochemical properties, lactic acid bacteria viability, and organoleptic characteristics of non-fat yogurt. J Food Technol Nutr. 2016;15(1):19-29.

- Nursyah PH, Jemmy A, Adithya Y. Analysis of antioxidant activity in green tea kombucha based on optimal fermentation time. Pharmacon – Journal Ilmiah Farm. 2017;6(4):67-74.

- Jooyandeh H, Behbahani BA. Development of a probiotic low fat set yogurt containing concentrated sweet pepper extract. Food Sci Nutr. 2024;12(7):4656-4666.

Crossref - Maruddin F, Ratmawati R, Fahrullah F, Taufik M. Characteristics of edible film based dangke whey with carrageenan addition. J Vet. 2018;19(2):291-297.

Crossref - Salee N, Chaiyana W, Anuchapreeda S, et al. Co-extract of green tea and black rice: incremental effect of antioxidant and anti-inflammatory properties and their freeze-dried double emulsion encapsulated powder. Int J Food Sci Technol. 2024;59(10):7550-7559.

Crossref - Ardiansyah E, Sa’adah NAM, Izati R, et al. Evaluation of Green Tea Yoghurt Enriched with Lacticaseibacillus paracasei E1 Microcapsules on Macrophage M1 Profile in High Fat-Fructose Diet Mice. Journal of Modern Science. 2025;11(1):113 -125.

Crossref - Zonus AT, Ghane M, Leila P. Effect of green tea powder supplementation on probiotic potential, antioxidant, physicochemical, and sensory properties of probiotic ice cream. J Food Sci Technol. (Iran). 2025;21(155):27- 40. https://www.sid.ir/paper/1490944/en

- Nugroho MR, Wanniatie V, Qisthon A, Septinova D. Physical and total properties of lactic acid bacteria (lab) of yogurt with different raw materialsof cow’s milk.

J Res Innov Anim. 2023; 7(2):279-286

Crossref - Peighambardoust SH, Golshan Tafti A, Hesari J. Application of spray drying for preservation of lactic acid starter cultures: a review. Trends Food Sci Technol. 2011;22(5):215-224.

Crossref - Soukoulis C, Panagiotidis P, Koureli R, Tzia C. Industrial yogurt manufacture: monitoring of fermentation process and improvement of final product quality. J Dairy Sci. 2007;90(6):2641-2654.

Crossref - Mucheru P, Chege F, Muchiri M. Physiochemical, proximate composition and microbial quality of a novel probiotic yoghurt fortified with purple-leaf tea (Camelias Sinensis). Afr J Food, Agric, Nutr Dev. 2024;24(12):25291-25308.

Crossref - Ali A, Javaid MT, Tazeddinova D, et al. Optimization of spray dried yogurt and its application to prepare functional cookies. Front Nutr. 2023;10:1186469.

Crossref - Wang H, Gao Y, Zhang H, Zhang Y, Li X, Li Y. Effects of heating treatment on functional and structural properties of proteins. Foods. 2023;12(8):1652.

Crossref - Zhou F, Rashwan AK, Xie J, Shamsi IH, Chen W. Cyclocarya paliurus leaf extract powder as a multifunctional additive in set – type yogurt : enhancing physicochemical, antioxidant, and andtidiabetic properties. Journal Zhejiang University Hangzhou China. 2024;310058:2-36.

Crossref - Amanto BS, Aprilia TN, Nursiwi A. Effect of blanching duration and leaf-picking formula on the physical, chemical, and sensory characteristics of fig leaf tea (Ficus carica). J Teknol Has Pertan. 2020;12(1):1-11.

Crossref - Rohman E, Maharani S. The role of color, viscosity, and syneresis on yogurt products. Edufortech. 2020;5(2):98-107

Crossref - Jeong CH, Ryu H, Zhang T, Lee CH, Seo HG, Han SG. Green tea powder supplementation enhances fermentation and antioxidant activity of set-type yogurt. Food Sci Biotechnol. 2018;27(5):1419-1427.

Crossref - Kusmiyati N, Massora M, Wicaksono ST. Potential analysis of cheese whey as an alternative medium for growth of the Lactobacillus casei group. J Biol El-Hayah. 2022;12(1):137-145.

Crossref - Jakubowska M, Karamucki T. The effect of storage time and temperature on the quality of natural yoghurt. Acta Sci Pol Zootechnica. 2019;18(4):29-38.

Crossref - Ramaiyuli R, Salvia S, Dewi M. animal nutrition science. Payakumbuh, Indonesia: Payakumbuh State Agricultural Polytechnic; 2022:41. https://id.scribd.com/document/680410383/Animal-Nutrition-Science.

- Walstra P, Wouters JTM, Geurts TJ. Dairy Science and Technology, 2nd ed. Boca Raton, FL: CRC Press; 2005.

Crossref - Nguyen L, Hwang ES. Quality characteristics and antioxidant activity of yogurt supplemented with aronia (Aronia melanocarpa) juice. Prev Nutr Food Sci. 2016;21(4):330-337.

Crossref

© The Author(s) 2025. Open Access. This article is distributed under the terms of the Creative Commons Attribution 4.0 International License which permits unrestricted use, sharing, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.