Customers Concerns regarding the consumption of both more secure and safer products along with being more natural have been the science of Food and production of foodstuffs one of the gentle. Different Methods of Preservation such as drying, addition of additives, freezing etc have introduced with the possibility of changing some food parameters like water activity. Indeed most ways to reach safer products arises from reduction of microorganism and with respect to the amount level of their microbial lethality. Recently the viewpoint of synergistic of using some preserving methods together has been lead to introduction of hurdle technology. Due to developments in intelligent application of hurdle technology as well as critical factors of food preservation & their interactions, currently hurdle technologies has become as prevalent as it could. Present contribution reviews the brief introduction about hurdle technology, its effects and future trends.

Hurdle technology, food preservation, Security, Food Safety, Additives, Hurdle Factors, Shelf Life.

Primarily, food preservation techniques are an inseparable part of production of foodstuffs in regards with overcoming pathogens with respect to extending shelf life as an often controversial issue, food scientist attempted to achieve to novel nondestructive food production methods, modern method of quality assessment accompanied by least occurring nutrient damages. Recently combination of preserving factors (hurdles); water activity, pH, heat treatment, application of herbal drug extract and etc which initially illustrated and heightened1. More than 50% of the reaped foodstuff is often vanished owing to putrefaction in developing nations because of the scanty knowledge for food preservation. According to FAO, one third of the total gathered foodstuff, in the globe is missing before it is used up. Consumer wants to use natural & fresh food which is a stressful condition for the food companies to launch a new technique for preservation2.

Currently different types of food are producing in the world which categorizes into some groups such as vegetables, fruits, nuts etc. The main concern regarding the food is their shelf life and shelf stability. Regarding vegetables mushroom is an example; Mushrooms are highly perishable and their shelf-life depends on processing, package properties and environmental conditions during storage and distribution. Some factors affecting Mushrooms, their texture can be affected by various factors like heat treatment and storage in pH ranges and showed that shear force exhibited similar trend to firmness but with distinguishable differences3.

The main theory of bringing hurdle technology up is severity of applying one preserving factor which can lead to degrade nutritional quality as a result of damages may occur to food substances. To have the wholesome foods accompanied and avoid undesirable changes attributed to non-effective methods (destructive methods), multi-hurdle approaches is considered as an appropriate alternative prior to increasing the intensity of a single hurdle factor i.e. combination of hurdles can emerge more synergistic affections, more reduction of pathogens along with more keeping nutrients.

In few recent decades, almost all of food products preserve by hurdle method and the amount of hurdle and the types of them are determined by empirical experiments, however it is still a challenge issue to the methods of assessing food stability4, 5.

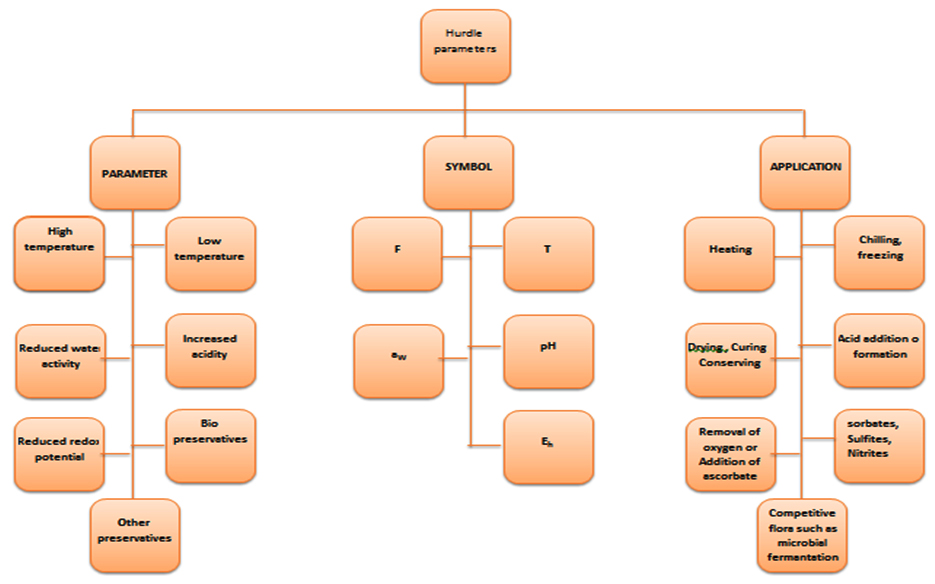

There are several factors affecting hurdle technology which have summarized in table 1.

Table (1):

Physical hurdle examples [7].

Examples |

|

|---|---|

Physical hurdles |

Aseptic packaging, Electromagnetic energy (microwave, radio frequency, pulsed magnetic fields, high electric fields),High temperatures (blanching, pasteurization, sterilization, evaporation, extrusion, baking, frying) , Ionizing radiation, Low temperatures (chilling, freezing), Modified atmospheres, Packaging films (including active packaging, edible coatings), Photodynamic inactivation, Ultra-high pressures Ultra sonication, Ultraviolet radiation |

Hurdle factors

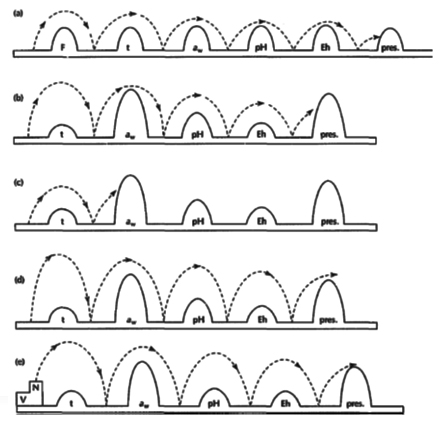

In traditional cases of food preservation, addition of sugar to produce jams, heating, deposition of antimicrobial agent from smoking onto food surface and so forth are considered hurdles. Since aforementioned factors have flavor-affecting properties contribute in sensory properties of final products. To achieve a good level of shelf life in terms of extending shelf life using hurdle technologies, they must arise at different stages in orders. Table 1 summarizes hurdle factors use in food industries.Depdning on the condition of product, a different series of hurdles, to overcome satisfactorilly the number of pathegns, adequate level of minimizing the lost of nutrients can be used, but it should be noted that in practice, they can operate simultneaously, synergitically, sequentially.Figure 3. Five examples of the hurdle effect used in food preservation. Symbols have the following meaning: F, heating; t, chilling; aw, low water activity; pH, acidification; Eh, low redox potential; pres., preservatives; V, vitamins; N, nutrients6.

Fig. 1. Hurdle parameters [6]

Fig. 1. Hurdle parameters [6]

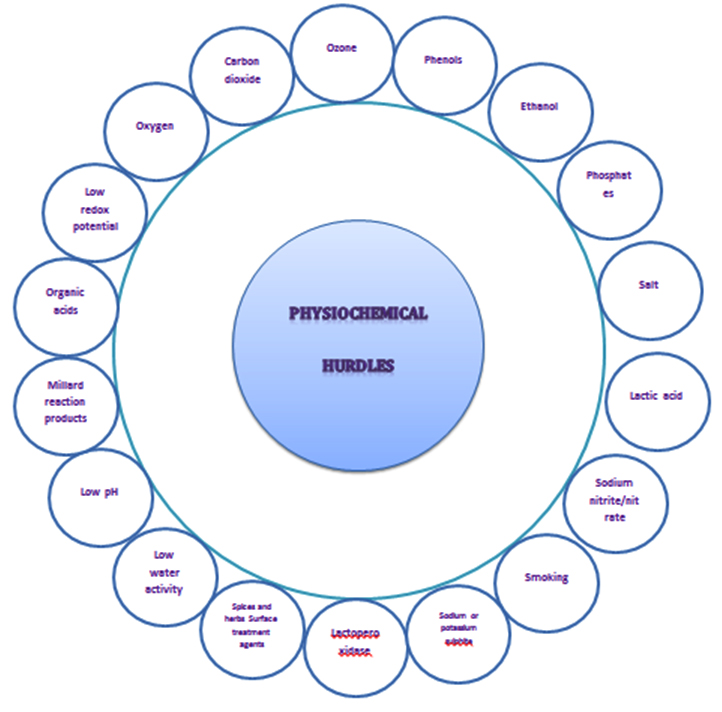

Fig. 2. Examples of physical hurdles [7]

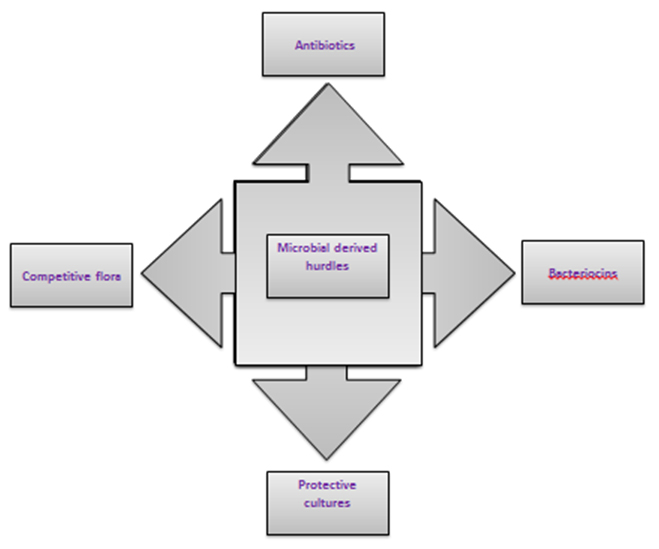

Fig. 3. Microbial derived hurdles [7]

Fig. 4. Five examples of the hurdle effect used in food preservation. Symbols have the following meaning: F, heating; t, chilling; aw, low water activity; pH, acidification; Eh, low redox potential; pres., preservatives; V, vitamins; N, nutrients [6]

Fig. 4. Five examples of the hurdle effect used in food preservation. Symbols have the following meaning: F, heating; t, chilling; aw, low water activity; pH, acidification; Eh, low redox potential; pres., preservatives; V, vitamins; N, nutrients [6]Application of hurdle technology

Saxena et al studied the combination of osmotic dehydration, infrared drying, and gamma radiation dose of 1 kGy on by which the final load of micro flora was less than detectable limits. They found that the best status of pineapple slices is observable in RTE intermediate moisture slices during 40 days compared to samples.Goyeneche et al. studied the application of principal component and hierarchical cluster analysis as a mathematical tool to select hurdle technologies (physical and chemical) to inhibit polyphenol oxidase (PPO) activity and color stability of minimally sliced radishes was presented8. They concluded PPO activity and color were reported initially (day zero) and after 4 d of refrigerated storage. Based on the mentioned tools and from the thirteen mono-hurdles technologies that were initially selected, eight hurdles were chosen as the best and combined in pairs. From those hurdles, the following double-hurdles were selected as those capable of retaining the product color: Ascorbic Acid (AA) þ Acetic Acid (ACA-05), AA þ NaCl-1, ACA-05þNaCl-1, AA þ Heat Treatment (TT-501), ACA-05 þ Ultrasound (US), Citric Acid (CA) þ AA, CA þ ACA-05, NaCl-1þUS. When comparing the best mono-hurdles (AA, TT-501, NaCl-1) to the best double hurdles, the following hurdles: AA, TT-501, CA þ ACA-05, NaCl-1þUS, CA þ AA and NaCl-1 were chosen as those capable of maintaining the typical color of radish slices with acceptable sensory parameters and enzyme inhibition after 4 d of storage.Wordon et al. carried out designing an appropriate hurdle technology using heat and ultrasound, the metabolic status of Saccharomyces cerevisiae in late exponential phase of growth was established using real-time fluorescent flow-cytometric analysis. The organism, suspended in physiological saline, was subjected for 5 min to either heat (55 or 60 °C) or ultrasound (20 kHz), or to a combination of both, and analysed for viable, membrane-injured and dead cells using thiazole orange (TO) and propidium iodide (PI). Analyses indicated that over a period of time, cells subjected to heat progressed from viable to membrane-injured, to death. In the heated preparations, the measured decline in viable cell population was principally due to membrane injury. When S. cerevisiae was treated with ultrasound (20 kHz, 124 µm), only viable and dead cell populations were detected. Scanning electron microscopy showed extensive boundary damage to cells after 1 min sonication. Ultrasound was rapidly microbicidal and cavitation-induced membrane damage was probably immediately lethal. The complete disintegration of cells undergoing sonication was slow and not the principal method of cell death. When S. cerevisiae was pre-treated with 1 min ultrasonication followed by immediate heating (55 or 60 °C), death rate at both temperatures tested was enhanced thus confirming synergism between the two hurdles. Real time fluorescent studies showed that ultrasound induced non-lethal intracellular injuries not associated with the membrane, making S. cerevisiae more susceptible to heat damage9.Gupta et al. found that Citric acid treatment in combination with gamma radiation and modified atmosphere packaging was employed as hurdles for control of microorganisms and extending shelf life of minimally processed French beans. Response surface methodology was used to optimize citric acid treatment and g-irradiation dose to obtain product with desired microbial and sensory quality. Optimum processing conditions (citric acid 8.4 g L_1; irradiation dose 0.7 kGy; 10 _C) resulted in modified atmosphere of 18% O2 and 4% CO2 at end of storage period. Under these conditions shelf life of the product could be extended by one week with acceptable sensory and nutritional quality as evaluated by total antioxidant, phenolics, flavonoids and vitamin C content10.Gabriel. studied This study evaluated the individual and combined efficacies of physical processing techniques such as heating, Dynashock multi-frequency ultrasound waves, ultraviolet-C (UV-C), and additives such as sodium benzoate, potassium sorbate, a- and b-Pinene for pasteurization of orange and apple juices against acid-adapted Escherichia coli O157:H7. In heated apple juice, log-linear inactivation of the test organism resulted in D values which were used to calculate for the recommended 5-log reduction process schedules (t5D) at 45, 50, 52, 55, and 60 °C equal to 481.5, 103.6, 45.0, 22.4, and 10.54 min, respectively. E. coli O157:H7 exhibited biphasic inactivation composed of a slow inactivation lag, followed by log-linear inactivation in ultrasound-treated juice. t 5D schedules were similarly calculated at 54.7 and 77.5 min for orange and apple juice, respectively. Lethal rate analyses in the ultrasound-treated apple juice revealed that 85% of the reduction in E. coli population was due to the heat liberated by cavitation. Combined ultrasound and UV-C treatment resulted in greater inactivation rates in both juices, with greater efficacy in apple juice. Supplementation of all tested additives, whether singly or in combination, similarly resulted in significantly shorter t5D schedules in both juices11.Chen et al. searched on Si-raw. Si-Raw is a raw cured meat (raw, cured meat fermented with steamed rice) produced by the aboriginal people of Taiwan. In order to prevent food poisoning or intoxication from botulism, new methods of monitoring the production base on hurdle technology were investigated. New methods investigated incorporated citric acid, sodium hypophosphite, Monascus anka mash, plum paste or lactic acid bacteria inoculum added separately to meat with steamed rice and salt to lower the Aw (water activity) and pH values of the products to control the microbial growth. Results showed that anaerobic bacterial counts, lactic acid bacterial counts and aerobic bacterial counts for the products of all treatments were less than 106, 105 and 102 cfu/g, respectively. Sodium chloride content of all products was above 5.46%, water activity was below 0.939 and pH value was below 4.27. IMP was lower and ATP and hypoxanthine were higher. ATP concentrations were higher in the samples which contained the anka mash. Result of sensory panel test indicated that most people preferred the products with added sodium hypophosphite. Except for the fact that the content of tryptamine in the sample with Monascus anka mash was higher, the amine concentrations for all treatments were lower than those of other fermented meat products. The amino acid nitrogen content was higher in the product made from raw meat treated with citric acid, but lower in the other products. Neither Clostridium botulinum nor Trichinella spiralis were detected in any of the treatments. The result may indicate that hurdle technology is effective for hygiene and safe producing Si-Raw12.Lee. Investigated that Escherichia coli O157:H7 is a member of the enterohemorrhagic group of pathogenic E. coli that has emerged as a foodborne pathogen of major public health concern. E. coli O157:H7 is highly tolerant of acidic pH and outbreaks attributed to this bacterium have been in many acidic foods which have pH level with similar to those of pickled products. Therefore, pickled vegetables, although acidic, may not safe. In pickling vegetables, the combination of preservation factors (heat, acetic acid, and salt) will contribute to increase the microbial safety. Recently, the concept of combining preservative factors for food preservation was developed, called ‘hurdle technology’. In hurdle technology, combination treatments are applied because it is expected that the use of combined preservative factors will have greater effectiveness at inactivating microorganisms than the use of any single factor. However, recent studies show that the combination of preservation factors can have unexpected antimicrobial activity. Therefore, this article includes an overall review of the microbial safety of fruits and vegetables, preservative method including major preservative factors used in pickling technology, concept and mechanism of hurdle technology and E. coli O157:H713.Sedghi et al. showed that Sodium nitrite has been always considered as one of the common additives due to its antibacterial effects on Clostridium botulinum and meat products’ color, however it produces cancer creating nitrosamine. Recently, organic acids and their salts such as lactates have been employed as antimicrobial compounds. Lactates also improve organileptic properties including color, texture and taste and antioxidant properties. Sodium lactate causes to more reduction of anaerobic spore former bacteria than nitrite, inhibits botulin produced by Clostridium botulinum. Sodium lactate produces a permanent reddish pink color through reduction of deoxymygloboline and producing deoxymyoglobuline. In this study, the decrease of sodium nitrite amount from 120ppm to 15ppm by adding sodium lactate / sodium diacetate led to achieve an acceptable product. The best results revealed through adding 3.0625% of sodium lactate / sodium diacetate in combination with 30ppm sodium nitrite. Results also exhibited more reduction of pathogens’ growth than nitrite, enhanced flavor slightly, but unable to produce reddish pink color as produced by nitrite. Results also exhibited that sodium lactate / diacetate cause to retard in microbial growth, reducing chemical change, enhance sensory properties, partially improvement in taste and texture. Although inappropriate color demonstrated sodium lactate / diacetate’s inability in red pink color production in 4th sample (contains 15 ppm nitrite), its synergy effect in combination with sodium nitrite on nitroso myoglobuline production has been proven, led to sodium nitrite reduction in sausages18.

Antibacterial Agents

Antibacterial peptides refer to those peptides with different numbers of amino acids and limitation of 100. Regarding the type, origin, size, and structure and activation way. They act against microorganisms vary from bacteria to viruses and etc. Aps categorizes in 4 groups ²-sheet, ±-helical, loop and extended peptides. Since APs mostly are rich in basic amino acid such as arginine they have a net positive charge. Perhaps may say that first time APs extracted from a basillus strain by which mice were protected against a kind of cocci infectious. During time, other antibacterial peptides discovered with affection on gram positive and negative bacteria even fungi. The target organs in which APs are findable varies from type to type. Mostly enzymatic activities are not critical property in classifying APs and they categorize based on the targeted microorganisms for each one. Antiviral peptides may act in 3 ways including disrupting of envelopes, blocking of receptors, preventing of viral particle entrance in host’s cells. For viral case, APs may not have the ability of competition with glycoproteins14.

Packaging

Developing of food packaging technologies has been caused to increase shelf life of perishable foods like meat and meat products. Recently, widely researches on the field of active packaging have performed. Active packaging not only improves shelf life, security properties, organoleptic properties and supplying of foodstuffs, but having preservative in them can widen their shelf life15.In addition, Different compounds such as starch, Gum like Psyllium, Chitosan used as biofilms, which is a new technology of packaging in which the chance of microbial entrance will reduce16, 17,19.Edible films are defined as thin layers that can be used as edible coatings on food or as a barrier between the food and the surrounding environments. Over the last ten years, because of more consumers demanding higher quality and shelf-life of food good research by food engineers on the edible coatings is done.Active packaging is a type of packaging at which changes packaged foodstuff conditions and leads to increase shelf life, organoleptic properties and foodstuff qualities. Active packaging includes application of food additives aiming at increasing of preservative affection of package materials. Different active packages include oxygen scavenger, moisture absorbent, and Carbon dioxide generator,

Overall the combination of various factors in the keeping quality and preservation methods of foodstuffs are inevitable to be optimized in any time. It must be noted that the hurdle technology makes minimal sensory and nutritional changes in the product which makes the product more valuable and acceptable than obtained by conventional methods and has become a boon for the efficient preservation of food products.

- Leistner, L. Hurdle effect and energy saving. In: Downey WK (ed) Food quality and nutrition. Applied Science Publishers, London, 1978; pp 553.

- Pundhir A., Murtaza N. Hurdle Technology-An Approach towards Food Preservation. Int J Current Microbiol App Sci., 2015; 4(7): 802-809.

- Akbarirad, H., Kazemeini S.M., Shariaty, M.A. Deterioration and some of applied preservation techniques for common mushrooms (agaricus bisporus, followed by lentinus edodes, pleurotus spp.). Journal of Microbiology, Biotechnology and Food Sciences., 2013; 2(6), 2398-2402.

- Levine, H, Slade, L. Water as a plasticizer: physico-chemical aspects of low-moisture. Polymeric systems. In: Franks F (ed) Water science reviews, vol 3. Cambridge University Press,Cambridge, 1988.

- Rahman, M.S. Applications of macro–micro region concept in the state diagram and critical temperature concepts in determining the food stability. Food Chemistry, 2012; 132:1679–1685.

- Leistner L and Gorris LGM. 1995. Food Preservation by hurdle technology. Trend in Food Science and Technology.,1995; 6: 35-37.

- Fellow, P.FOOD PROCESSING TECHNOLOGY Principles and Practice Second Edition. Director, Midway Technology and Visiting Fellow in Food Technology at Oxford Brookes University Published by Woodhead Publishing Limited Abington Hall, Abington Cambridge CB1 6AH, England Published in North and South America by CRC Press LLC 2000 Corporate Blvd, NW Boca Raton FL 33431 USA, 2000.

- Goyeneche, R. Roura, S. Di Scala, K. Principal component and hierarchical cluster analysis to select hurdle technologies for minimal processed radishes. LWT – Food Science and Technology., 2014; 57, 522-529.

- Wordon, B.A. , Mortimer, McMaster L.D. Comparative real-time analysis of Saccharomyces cerevisiae cell viability, injury and death induced by ultrasound (20 kHz) and heat for the application of hurdle technology, Food Research International., 2012; 47,134–139.

- Gupta, S., Chatterjee, S., Vaishnav, J., Kumar, V., S. Variyar, P, Sharma, A. Hurdle technology for shelf stable minimally processed French beans (Phaseolus vulgaris): A response surface methodology approach. LWT – Food Science and Technology., 2012; 48, 182-189.

- Gabriel, A, A. Combinations of selected physical and chemical hurdles to inactivate Escherichia coli O157:H7 in apple and orange juices. Food Control., 2015; 50, 722-728.

- Chen, M., Lin, Y., Tsai, H., Kuo, H. Efficiency of Hurdle Technology Applied to Raw Cured Meat (Si-Raw) Processing. Asian-Australasian Journal of Animal Sciences 2002; 15(11): 1646-1652.

- Lee, S. Microbial Safety of Pickled Fruits and Vegetables and Hurdle Technology. Internet Journal of Food Safety., 2004; 4, 21-32.

- Sharifi Gharbi, S.O., Jashidi, M, Kiani, M., Shariati, M.A. Application of Peptide Compounds as Anti-Bacterial Agent versus Bacteria. International Journal of Pharmaceutical Research & Allied Sciences, 2016; 5(3): 352-355.

- Kaviani, M., Azizzadeh, S., Tomovska, J., Hosseini, M., Shariati, M.A. A Short Review on Application and Comparison of Novel Active Packaging and MPA in Meat Packaging and Meat Products, International Journal of Pharmaceutical Research & Allied Science.s, 2015; 4: 2,

- Banasaz, S., Hojatoleslamy, H., Razavi, S,H., Hoseini, E., Shariaty, M.A. The Effect of Psyllium seed gum as an edible coating and in comparison to Chitosan on the textural properties and color changes of Red Delicious Apple, International Journal of Farming and Allied Sciences, 2013; 18, 651-657.

- Hooman, M., Behfar S., Shariati, M. A, Kaviani, M., Atarod, S. A Review on biodegradable starch based film. The Journal of Microbiology, Biotechnology and Food Sciences, 2015; 4(5), 456.

- Sedghi, H., Mohamadi Sani, Ali., Najaf Najafi, M.asood, Shariati, M, A. Effect of sodium lactate / sodium diacetate in combination with sodium nitrite on physiochemical, microbial properties and sensory evaluation of cow sausage. Potravinarstvo, 2014; 8(1), 239-246.

- Kaviani, M., Shariati ,M.A., Joshevska, E., Tomovska, J., Vanaei, M. Effects of Chitosan and Aloe Vera Gel Coating on Quality Characters of Pistachio. J Nutr Health Food Eng 2015; 2(1): 00042.

© The Author(s) 2016. Open Access. This article is distributed under the terms of the Creative Commons Attribution 4.0 International License which permits unrestricted use, sharing, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.