ISSN: 0973-7510

E-ISSN: 2581-690X

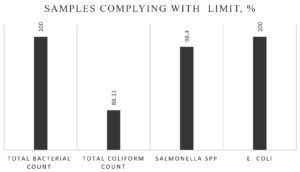

Milk is an important part of human nutrition, especially for children, and is rich in proteins, essential fatty acids, vitamins, minerals, and biofunctional elements. Despite its benefits, milk is prone to microbial contamination due to its composition and handling. Therefore, this study focused on assessing the microbial levels and the frequency of water adulteration in pasteurized milk samples from Addis Ababa, Ethiopia, which represents a critical market for dairy products. A total of 66 pasteurized milk samples from various brands across all sub-cities of Addis Ababa were analyzed. Microbial quality was evaluated using Total Bacterial Count (TBC), Total Coliform Count (TCC), Escherichia coli, and Salmonella detection. Density analysis was conducted to detect water adulteration. Additionally, handling practices at retail were assessed through a questionnaire survey. A considerable portion of pasteurized milk samples exhibited deviations in density from Ethiopian (31.6%) and East African standards (18.3%), suggesting potential water adulteration. Microbial analysis revealed that while all samples met TBC (100%) and E. coli (100%) standards, a notable proportion exceeded the TCC (88%) limit, thereby indicating inadequate processing or post-pasteurization contamination. Salmonella (98%) was absent in most samples tested. Overall, this study underscores critical issues with pasteurized milk quality in Addis Ababa, including frequent water adulteration and elevated microbial contamination, which pose risks to both nutritional value and consumer health. Therefore, strengthening quality control measures and enhancing hygiene practices throughout the dairy distribution chain are imperative to guarantee milk safety and compliance with international standards.

Adulteration, Dairy Industry, Milk Density, Microbial Quality, Pasteurized Milk

Milk is an important component of the human diet for all age groups, particularly children. Milk provides high-quality proteins with essential amino acids, fatty acids, vitamins, minerals, and energy.1,2 Moreover, milk contains peptides, nucleotides, oligosaccharides, immunoglobulins, and other biofunctional elements that add to its nutritional value.3 As health concerns have increased, milk quality has become a major focus.

Food adulteration is a global problem, especially in underdeveloped countries, where policies and monitoring are weak.4 Milk is often adulterated, either intentionally or accidentally, which lowers its quality and harms public health.5 Water, which may contain bacteria, toxic substances, or even feces,6 is often added to milk to meet demand, compete in the market, or increase profit.7,8 Moreover, water addition, cream removal, and high temperatures reduce milk density.9 Adulteration of milk is a serious health concern in Ethiopia as it lowers the nutritional value of milk, introduces harmful bacteria, poses health risks, and causes economic losses to consumers.4,10,11 Water adulteration is widespread, reduces product quality, and damages consumer trust.12

Milk is susceptible to microbial contamination because its high moisture content, neutral pH, and rich nutrients are ideal for microbial growth, leading to rapid spoilage.13,14 Microbial contamination not only reduces the nutritional value of milk but also poses a risk to consumer health. Furthermore, microbial contamination can occur at any stage of production, processing, or delivery.15,16 Although raw milk is nutritious, it can cause illnesses that have been linked to disease outbreaks and deaths.17 Pasteurization is the most common method used to ensure milk safety.18 However, the safety of pasteurized milk depends on the quality of raw milk, heat treatment, storage, and contamination risk after processing.19 Disease outbreaks linked to pasteurized milk indicate the need for strict safety measures.20-23

In Ethiopia, milk production and sale often lack proper quality control.24 Most milk (approximately 95%) is sold through informal systems, rendering quality checks difficult.15 Understanding the microbial and chemical composition of milk from smallholder producers is important to improve milk quality. Therefore, this study aimed to investigate water adulteration, assess microbial quality, and evaluate milk handling practices at the retail level. These results provide insights into the safety and quality of milk produced in this region.

Study area

The study was conducted in Addis Ababa, the capital of Ethiopia, where pasteurized milk is highly consumed, second to butter made from yogurt.13 Ethiopia has 32 milk processing facilities distributed across various regions, with Addis Ababa and nearby areas serving as key markets for dairy products. The main products of these processing plants are pasteurized milk, yogurt, and various types of cheese, and pasteurized milk accounts for approximately 83.4% of total dairy production in the country.25

Sample size and sampling

A cross-sectional study was conducted in all 11 sub-cities of Addis Ababa to ensure city-wide representation. A total of 66 pasteurized milk samples consisting of six samples from each sub-city were collected. The sample size was chosen to represent a diverse range of milk products. The samples were randomly selected from retail outlets with a sampling frame of industrially processed and packaged pasteurized milk, based on the availability of different brands in the market (Table 1).

Table (1):

Pasteurized milk samples collected from sub-cities and their corresponding brands

No. |

Sub-cities |

Number of samples |

Brands |

|---|---|---|---|

1 |

Arada |

6 |

A, C, G, G, I, E |

2 |

Kolfe Keranio |

6 |

A, F, I, G, I, L |

3 |

Addis Ketema |

6 |

G, F, H, C, D, A |

4 |

Akaki Kality |

6 |

C, F, I, L, G, I |

5 |

Gulele |

6 |

G, G, D, D, F, D |

6 |

Kirkos |

6 |

D, C, C, G, A, K |

7 |

Bole |

6 |

E, G, J, B, I, L |

8 |

Lemikura |

6 |

H, B, C, C, J, I |

9 |

Yeka |

6 |

C, K, E, G, J, E |

10 |

Lideta |

6 |

A, G, I, K, L, B |

11 |

Nifas Silk Lafto |

6 |

E, K, I, D, A, D |

The samples were collected between March and May 2023. Milk was collected in its original packaging and stored under cold conditions during transport to maintain its quality. The samples were taken to the Ethiopian Food and Drug Authority laboratory for testing. In addition to sample collection, a questionnaire was used to record retailers’ milk handling practices, such as storage conditions, worker hygiene, and refrigerator cleanliness.

To ensure freshness, milk was collected from the retail chains early in the morning. Each sample was transported in a cool box and later stored at 4 °C in the laboratory until analysis. All procedures followed established protocols.26

Handling practices of pasteurized milk

A semi-structured questionnaire and direct observations were used to assess milk-handling practices among retailers from March to May 2023. The information collected included how milk was transported and stored, as well as hygiene conditions. Observations were rated on a 10-point scale, with 10 indicating excellent practices, such as proper cold storage (0-4 °C) and clean facilities, and lower scores reflecting inadequate handling. Milk samples were collected after laboratory testing.

Density Assessment

The density of the pasteurized milk was measured using a lactometer to check for water adulteration. Milk was poured into a measuring cylinder, and a lactometer reading was taken. Temperature corrections were applied by adding or subtracting 0.2 g/mL milk for each degree above or below the calibration temperature, respectively. This ensured accurate density measurements.27

Sample preparation

Milk samples were thoroughly mixed by gently inverting the package 25 times to evenly distribute the microorganisms. The mixture was allowed to settle to prevent foaming, and a sterile pipette was used to extract 1 mL of milk. The sample was mixed with 9 mL of buffered peptone water to obtain a 1:10 dilution. The mixtures were blended for 10 s using a vortex mixer before further testing.28

Microbial quality analysis of pasteurized milk

Media preparation

Media were prepared according to the manufacturer’s guidelines. Buffered peptone water was sterilized at 121 °C for 15-20 min and cooled to 30 °C before use. This ensured reliable conditions for microbial testing.29

Total Bacteria Count (TBC)

TBCs were determined using a standard plate count agar (SPCA). Milk samples were diluted up to 1:107, and 0.1 mL of the diluted sample was spread on plates containing SPCA. Plates were incubated at 32 °C for 48 h, and colony counts between 30 and 300 colony forming units (CFU)/mL were used for analysis.30,31

Total Coliform Count (TCC)

Coliform bacteria were assessed using violet red bile agar (VRBA). Milk samples were diluted up to 1:105, and 0.1 mL of milk was plated on VRBA plates. Plates were incubated at 32 °C for 24 h, and dark-red colonies were counted. Gas production in the subsequent tests confirmed the presence of coliforms.29,31

Escherichia coli

Escherichia coli presence was tested by subculturing positive coliform samples in E. coli broth and incubating at 44.5 °C for 24 h. Gas production indicated the presence of E. coli and was further confirmed using eosin methylene blue agar and biochemical tests such as indole and methyl red assays.32

Salmonella

Salmonella testing followed the ISO guidelines. The samples were enriched in peptone water and Rappaport-Vassiliadis broth before being cultured in xylose lysine deoxycholate, Bismuth sulfite agar, and Hektoen enteric agar media. Colony confirmation was performed using the triple sugar iron test and Salmonella-specific antisera.33

Statistical analysis

Statistical analyses were performed using SPSS version 20. The data were analyzed in triplicate, and the averages and standard deviations were calculated. The results were compared to Ethiopian standards for pasteurized milk.34 Handling practices were analyzed as percentages using Excel.

Effects of handling at retail on microbial safety

Among the milk samples, 14 revealed signs of inadequate handling practices, whereas 52 demonstrated proper storage practices. A notable concern was the lack of cold storage facilities, which contributed to the compromised storage quality. The microbial prevalence in samples associated with poor handling (18.2%) was higher than that in samples stored appropriately (10.2%) (Table 2).

Table (2):

Assessment results of pasteurized milk-handling practices

Handling Practices |

Poor and Good Storage Conditions n (%) |

|---|---|

Poor Handling Practices |

14 (18.2%) |

Good Handling Practices |

52 (10.2%) |

Density

The average density of the 66 pasteurized milk samples was 1.022 ± 0.0046 g/mL. The sample density ranged between 1.013-1.031 g/mL, which deviated from the Ethiopian pasteurized liquid milk standard34 of 1.026-1.032 g/L, at 20 °C. Moreover, a substantial proportion (68.4%) of the pasteurized milk samples had densities lower than the minimum permissible limit, and only 31.6% of the samples met the acceptable criteria, representing less than one-third of the total samples (Table 3).

Table (3):

Density of pasteurized milk samples sourced from Addis Ababa and compliance with Ethiopian and East African Standards

Samples |

Density, g/mL |

Samples complying with CES 279:2021 limit (1.026-1.032 g/mL), % |

Samples complying with EAS 69:2006 limit (1.028-1.036 g/mL), % |

|---|---|---|---|

Pasteurized milk, n (66) |

1.022 ± 0.0046 |

31.6 |

18.3 |

Density values are provided as the mean ± standard deviation. CES, Ethiopian standard; EAS, East African standard

Approximately 81.7% of the study samples failed to meet the East African Standard (EAS) for pasteurized milk, leaving only 18.3% within the defined limits. These findings underscore the deviations in milk density from established standards, revealing a noteworthy disparity that warrants further investigation.

Microbial quality

A range of l-0.51 × 104 CFU/mL was detected across all samples, and all samples adhered to CES 279:2021 for pasteurized milk. Further analysis of the microbial assessment (Table 3), revealed that total coliforms in the samples was within the range of 0.30-110 CFU/mL (Table 4).

Table (4):

Ethiopian Standard Compliance and microbiological quality of pasteurized milk samples taken from Addis Ababa (n = 66)

Microorganisms |

Range (CFU/mL) |

Maximum limit (CFU/mL) as per (35) |

|---|---|---|

Total bacterial count |

1-0.51 × 104 CFU/mL |

|

Total coliform count |

0.30 – 110 CFU/mL |

10 |

Salmonella spp. |

Suspected in one sample |

Nil |

Escherichia coli |

Nil |

Nil |

Salmonella contamination was suspected in the samples; however, subsequent analysis confirmed its absence in all samples. Interestingly, none of the samples contained E. coli, indicating satisfactory adherence to Ethiopian standards.34 This observation signified that the overall microbial load across all samples remained below the stipulated threshold, thereby reinforcing the robust compliance of the samples with established quality standards.

A detailed microbial assessment revealed that 88.33% of the samples complied with the Ethiopian standard for TCC,34 whereas 11.67% exceeded the specified limit (Figure). Salmonella was initially suspected in 1.6% of the samples; however, confirmatory tests showed its absence in all cases. Additionally, all samples (100%) were free of E. coli and adhered to the acceptable limits for total bacterial counts (Figure).

Milk density is a crucial parameter in the dairy industry because it reflects the concentration of milk mass per unit volume. A higher density indicates more concentrated milk, whereas a lower density suggests dilution. This parameter is essential for quality control and the detection of adulteration, which can affect both the nutritional value and shelf life of milk.35,36 Considering that the addition of water or other substances alters milk density, the reduced density found in the pasteurized milk samples in this study supports the possibility of water adulteration.

National, regional, and international standards define the acceptable density ranges for pasteurized milk. In this study, 68.4% and 81.7% of the samples did not meet Ethiopian and East African standards, respectively. This noncompliance indicates potential issues with nutritional quality and raises concerns about possible microbial contamination.37 The average density measured was 1.022 g/mL, which aligns with similar studies conducted in Gondar, Ethiopia, which reported an average density of 1.021 g/mL.38 Water adulteration is notably prevalent in milk processing facilities because of the residual water in handling and storage containers resulting from inadequate cleaning and drying practices.37

Older factory systems may introduce water through technical faults that are often driven by economic factors.39 Approximately 61.2% of samples from Addis Ababa had lower density, with higher chances of added water, a finding consistent with this study.40 In South Africa,39 a higher prevalence of water adulteration in pasteurized milk than in raw bulk milk was reported, with an average of 21 ± 14.6%.

The presence of adulterants in more than half of the pasteurized milk samples underscores notable water adulteration. Therefore, careful packaging is critical for preventing inadvertent water inclusion.41 In China, water adulteration is largely driven by high demand and limited supply.42 In Kolkata, India,43 64.52% of milk samples were adulterated with water, whereas44 no significant water addition was reported in Sudan; however, over 95% adulteration was found in some regions.4 In Turkey,45 poor hygiene in milk handling was found, with 30% of samples adulterated with contaminated water, which is a lower prevalence than that in this study. In Northern and Southern Omdurman,46 vendors found high levels of water adulteration, and milk samples from dairy shops and street vendors in Egypt exhibited wide-ranging adulteration rates of 4.2-47.9%.47 In Faisalabad, Pakistan,48 97% of milk samples from school cafeterias and 93% from communal areas contained added water, whereas49 a 73% adulteration rate was observed in Pakistan. Moreover, El-Zubeir et al.39 found higher adulteration levels in industrial settings, indicating that water adulteration may be accompanied by the addition of other substances to maintain milk density and color, thereby emphasizing the need for strict quality control procedures throughout the dairy value chain.

The high prevalence of water adulteration in the samples used in this study raises public health concerns. Watered milk is nutritionally inadequate and may contribute to malnutrition, particularly in children and other vulnerable populations. Given that diluted milk may also have reduced antimicrobial properties, it increases the risk of microbial contamination, thereby affecting overall food safety.50

The microbiological conditions of pasteurized milk are also of concern. In this study, 30% of the samples contained coliforms that exceeded the Ethiopian standard limit, indicating potential issues with processing or post-pasteurization contamination. Considering that pasteurization should eliminate coliforms, their presence in these samples suggests recontamination after pasteurization.5,51,52 Furthermore, high coliform counts suggest inadequate production procedures.53 and unsanitary processing practices.54

The TCC was in this study was higher than that reported by Faraz et al.48 in Sudan and Iran, but lower than that reported by Korma et al.55 in Ethiopia. Mikru et al.56 found a mean TCC of 3.22 log10 CFU/mL at the factory level that increased to 3.48 log10 CFU/mL at the market, which exceeded both Ethiopian and East African standards. This suggests post-pasteurization contamination and potential temperature abuse during transportation and storage.

Unlike this study, which found no E. coli in pasteurized milk, Alemu et al.36 reported higher E. coli levels than that reported by Faraz et al.48 Fecal contamination during milking is a major cause of E. coli infection.

The presence of coliforms, particularly E. coli, in pasteurized milk is a major public health concern. Coliforms are indicators of fecal contamination and poor hygiene practices, which result in waterborne and foodborne illnesses, such as gastroenteritis, particularly in immunocompromised individuals.57 This highlights the critical need for strict hygiene practices and temperature control in the milk supply chain to prevent post-pasteurization contamination and safeguard consumer health.

Salmonella prevalence in this study was 1.6%, which is higher than that found by Alemu et al.36 but lower than found by Welearegay et al.,58 who found no Salmonella in pasteurized milk from retail markets in Hawassa, Ethiopia. Similar findings were reported in Trinidad.59 The substandard microbial conditions of milk in this study were most likely a result of poor hygiene practices and inadequate cooling systems along the milk supply chain.60 Salmonella is a common cause of foodborne illnesses, which manifest as fever, diarrhea, and abdominal cramps. This poses a considerable health risk, particularly for children and vulnerable groups who may have heightened sensitivity to foodborne pathogens.61

In conclusion, this study revealed notable issues with the quality of pasteurized milk, including frequent water adulteration and elevated coliform counts, which compromise nutritional value and safety. A substantial proportion of the samples failed to meet the established density standards, indicating potential economic adulteration. Additionally, poor hygiene and inadequate cooling during processing and storage contributed to microbial contamination. Therefore, strengthening quality control measures, improving hygiene practices, and ensuring proper temperature control are essential for milk safety and compliance with standards. This will protect public health and ensure that milk remains a safe and nutritious food source for the population.

Limitations Study

This study is limited by its one-time sampling approach, which may not have captured variations over time. In addition, the relatively small sample size limits the generalizability of the findings. Larger and more diverse samples would provide more comprehensive insights.

ACKNOWLEDGMENTS

The authors would like to thank Addis Ababa University for giving the chance to perform this study. The authors also want to express their sincere appreciation to all those who provide their invaluable contributions and support.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

AUTHORS’ CONTRIBUTION

HT conceived the study, collected, and analyzed the data and interpreted the results. GD and AT contributed to the interpretation of the main findings. HT wrote the manuscript. GD and AT reviewed and edited the manuscript. All authors read and approved the final manuscript for publication.

FUNDING

None.

DATA AVAILABILITY

All datasets generated or analyzed during this study are included in the manuscript.

ETHICS STATEMENT

Not applicable.

- Abunna F, Tasew N, Ragassa F, Ayana D, Amenu K. Handling practices, quality, and safety of milk along the dairy value chains in selected sub cites of Addis Ababa, Ethiopia. Biomed J Sci. 2019;13(1):96529665.

Crossref - Melese A, Wolde T. Bacteriological quality and safety of raw cow’s milk in and around Jigjiga City of Somali region, Eastern Ethiopia. Int J Res Stud Biosci. 2015;3(5):48-55.

- Haug A, Hostmark AT, Harstad OM. Bovine milk in human nutrition-a review. Lipids Health Dis. 2007;6:25.

Crossref - Azad T, Ahmed S. Common milk adulteration and their detection techniques. International Journal of Food Contamination. 2016;3:22.

Crossref - Omore A, Arimi S, Kaugethe E, et al. Assessing and managing milk-born health risk for the benefit of consumers in Kenya. Smallholder Dairy (R and D) project (SDP), Nairobi, Kenya. 2002.

- Reddy DM, Venkatesh K, Reddy CV. Adulteration of milk and its detection: a review. Int J Chem Stud. 2017;5(4):613-617.

- Moonajilin MS, Islam MS, Paul R. A study on milk adulteration of SavarUpazila in Bangladesh. Int J Commun Med Public Health. 2018;5(11):4670-4465.

Crossref - Yadav AK, Gattupallil M, Dashora K, Kumar V. Key milk adulterants in India and their detection techniques: a review. Food Anal Methods. 2022;16(12):499-514.

Crossref - Yilma Z, Guernebleich E, Sebsibe A. A review of the Ethiopian dairy sector, in: FAO Report, 2011;83.

- Walstra P, Jenness R, Badings HT. Dairy chemistry and physics. 1st ed. Wiley-Inter science, New York. 1984.

- Salih MAM, Yang S. Common milk adulteration in developing countries cases study in China and Sudan: a review. J Adv Dairy Res. 2017;5(4):192.

Crossref - Sebho HK, Meskel DH. Determination of adulteration and chemical composition of raw milk sold in Hossana town, South Ethiopia. J Dairy Vet Sci. 2018;6(5):555699.

Crossref - Mamo T, Haji J, Bekele A, Teklewold T, Berg S, Moore HL. Dairy product consumption behavior of Addis Ababa city households: A multivariate probit model approach. Ethiop J Sci Technol. 2022;13(1):71-86.

- Merhawit R, Taddele H, Afera B, Bsrat A. Bacteriological quality assessment of milk in dairy farms, cafeterias and wholesalers in Adigrat, Tigray, Ethiopia. Eur J Biol Sci. 2014;6(4):88-94.

Crossref - Shaikh N, Soomro AH, Sheikh SA, Khaskheli M. Extent of water adulteration and its influence on physical characteristics of market milk. Pak J Nutr. 2013;12(2):178-181.

Crossref - Tekliye M. Handling practices, evaluation of adulteration and microbial quality of raw cow milk around Bahir Dar, Ethiopia. Food Science and Quality Management. 2017; 61:1-9

Crossref - Abdoul-latif FM, Somda MK, Fourreh AE, et.al. Evaluation of microbiological quality of raw milk from farmers and dairy producers in six districts of Djibouti. Journal of Food Hygiene and Safety. 2017;2(3):1000124.

- Patel KN, Patel A. Milk adulteration and their detection technique. International Journal of Scientific Development and Research. 2021;6(5):190-205.

- Sarkar S. Microbiological safety concerns of raw milk. J Food Nutri Diete. 2016;1(2):1-7.

Crossref - CDC (Centers for Disease Control and Prevention). Outbreak of Listeria monocytogenes infections associated with pasteurized milk from a local dairy-Massachusetts, 2007. Morb Mortal Weekly Report. 2008;57:1097-1100.

- Schmid D, Fretz R, Winter P, et. al. Outbreak of staphylococcal food intoxication after consumption of pasteurized milk products, June, Austria, Wien Klin Wochenschr. 2009;121(3-4):125-131.

Crossref - Koch J, Dworak R, Prager R, et.al. Large listeriosis outbreak linked to cheese made from pasteurized milk, Germany, 2006-2007. Foodborne Pathog Dis. 2010;7(12):1581-1584.

Crossref - Jackson KA, Biggerstaff M, Tobin-D’Angelo M, et.al. Multistate outbreak of Listeria monocytogenes associated with Mexican-style cheese made from pasteurized milk among pregnant, Hispanic women. J Food Prot. 2011;74(6):949-953.

Crossref - Hiwot D, Savoinni G, Cattaneo D, Gabriella S, Martino P. Bacteriological quality of milk in raw bovine bulk milk in the selected milk collection centers: Smallholder dairy processing Ethiopia. Journal of Veterinary Science & Animal Husbandry. 2016;4(2).

Crossref - Pradeep S, Lakshminarayana P, Varsha R, Kota SK. Screening of adulterants in milk. Int J Curr Res Rev. 2017;8(12):25-29.

- Getabalew M, Alemneh T, Akeberegn D. Dairy production in Ethiopia existing scenario and constraints. Biomed J Sci Tech Res. 2019;16(5):12304-12309.

Crossref - Desye B, Bitew BD, Amare DE, Birhan TA, Jetanehc A, Gufue ZH. Quality assessment of raw and pasteurized milk in Gondar city, Northwest Ethiopia: A laboratory-based cross-sectional study. Heliyon. 2023;9(3):e14202.

Crossref - ISO. BAS EN ISO 6887-5:2012: Microbiology of food and animal feeding stuffs – Preparation of test samples, initial suspension, and decimal dilutions for microbiological examination – Part 5: Specific rules for the preparation of milk and milk products. Bosnia and Herzegovina Institute for Standardization, Sarajevo, Bosnia, and Herzegovina. 2012.

- APHA, (American Public Health Association). Standard Methods for the Examination of Dairy Products. Washington. 1992;213-223.

- Murphy SC, Boor KJ. Sources and Causes of High Bacteria Counts in Raw Milk: an Abbreviated Review, Cornell University, Ithaca. NY. 2005;1-12.

- Kiiyukia C. Laboratory Manual of Food Microbiology for Ethiopian Health and Nutrition Research Institute, in: UNIDO Project (YA/ETH/03/436/11-52). 2003;1-197.

- Harrigan WF. Laboratory Methods in Food Microbiology Gulf Professional Publishing. 1998;09:28-532

- ISO, 6579-1:2017: Microbiology of the food chain – Horizontal method for the detection, enumeration and serotyping of Salmonella, Edition 1.

- Ethiopian standard: Pasteurized liquid milk specification (ES 279/2021). The Quality and Standards Authority of Ethiopia, 2009;Ethiopia.

- Tessema A, Tibbo M. Milk quality control. Technical Bulletin. 2009;2:1-12.

Crossref - Tesfaye A, Kebede G, Tadesse Y. Physicochemical and microbiological quality and safety of brand pasteurized milk produced and sold in Bishoftu, Ethiopia. Food Science and Quality Management. 2023;61:25.

Crossref - Haftom Z, Dawit A , Woldegiorgis AZ. Nutritional quality and adulterants of cow raw milk pasteurized, and cottage cheese collected along value chain from three regions of Ethiopia. Heliyon. 2023;9(5):e15922.

Crossref - Asrat A, Yilma Z. Boditti town and its surrounding, South Ethiopia. Scholarly Journal of Agricultural Science. 2014;4(10):512-516.

- El-Zubeir IEM, Gabriechise V, Johnson Q. Comparison of chemical composition and microbial profile of raw and pasteurized milk of the Western Cape, South Africa. Int J Dairy Sci. 2008;3(3):137-143.

Crossref - Minten MB, Habte Y, Baye K, Tamru S. Food safety, modernization, and food prices: evidence from milk in Ethiopia. International Food Policy Research Institute. 2018;146.

- Wanjala GW, Mathooko FM, Kutima PM, Mathara JM. Prevalence of adulteration and inhibitory substances in raw and pasteurized milk marketed in Nairobi region. Asian Food Science Journal. 2018;3(2):1-8.

Crossref - Ota Y, Hasumura M, Okamura M, et al. Chronic toxicity and carcinogenicity of dietary administered ammonium sulfate in F344 rats. Food Chem Toxicol. 2006;44(1):17-27.

Crossref - Padmayathi B, Ramakirshina VR. The physicochemical quality of commercial ice, a case study of urban and rural settlement. Int J A P S BMS. 2012;1(2):115-119.

- Rideout TC, Liu Q, Wood P, Fan MZ. Nutrient utilization and intestinal fermentation are differentially affected by the consumption of resistant starch varieties and conventional fibers in pigs. Br J Nutr. 2008;99(5):984-992.

Crossref - Salman AMA, Hamad IM. Enumeration and identification of Coliform bacteria from raw milk in Khartoum State. Sudan Journal of Cell & Animal Biology. 2011;5(7):121-128.

- Asged AAM, El-Zubeir IEM. Occurrence of adulterants and preservatives in the milk sold in rural areas of Omdurman, Sudan. Veterinary Medicine, and Public Health Journal. 2021;2(3):64-72.

Crossref - Ali MAI, El-Loly MM, Ahmad RO. A preliminary detection of physical and chemical properties, inhibitory substances and preservatives in raw milk. Journal of Food Safety. 2012;14:93-103.

- Faraz A, Lateef M, Mustafa MI, Akhtar P, Yaqoob M, Rehma S. Detection of adulteration, chemical composition and hygienic status of milk supplied to various canteens of educational institutes and public places in Faisalabad. The Journal of Animal and Plant Sciences. 2013;23(1 Suppl.):119-124.

- Shabir BG, Khaskheli M, Soomro AH, Nizamani ZA. Detection and extent of extraneous water and adulteration in milk consumed at Hyderabad, Pakistan. Pak J Food Nutr Sci. 2014;2(2):47-52.

Crossref - Sara OS, Abbas RZ, Asrar R, et.al. Milk adulteration and emerging health issues in humans and animals (A review). Continental Vet J. 2021;1(1):1-8.

- Woldemariam HW, Asres AM. Microbial and physicochemical qualities of pasteurized milk. J Food Process Technol. 2017;8(1):1000651.

Crossref - Van Den Berg JCT. Dairy technology in the tropic and subtropics. Center for Agricultural Publishing and Documentation (Pudoc). Wagneningen, The Netherlands. 1988.

- Walstra P, Geurts TJ, Noomen A, Jellema D, Van Boekel MAJS. Dairy technology principles of milk properties and processes. Marcel Dekker Inc, New York. 1999.

Crossref - Richardson G.H. Standard methods for the examination of dairy products (15th edn). American Public Health Association, Washington DC, USA. 1985.

- Korma H, Nurfeta A, Negera E. Microbiological quality and safety of milk production and marketing in Hawassa district, Ethiopia. Afr J Microbiol Res. 2018;12(25):587-594.

Crossref - Mikru A, Adani M, Dobo B. Microbial hazard analysis in the pasteurized milk production value chain at a commercial dairy plant in Hawassa, Southern Ethiopia. Advances in Dairy Research. 2021;9(4):254.

- Joshua SG, Ayse E, Colford Jr JM. Coliform bacteria as indicators of diarrheal risk in household drinking water: systematic review and meta-analysis. PLOS ONE. 2024;9(9):e107429.

Crossref - Welearegay H, Yilma Z, Tekle-Giorgis Y. Challenges and opportunities of milk production under different urban dairy farm sizes in Hawassa City, Southern Ethiopia. Afr J Agric Res. 2012;7(26):3860-3866.

Crossref - Hosein A, MuNoz K, Sawh K, Adesiyun A. Microbial load and the prevalence of Escherichia coli, Salmonella spp. and Listeria spp. in ready-to-eat products in Trinidad. Food Sci J. 2008;2(1):23-28.

Crossref - Mitiku E, Yirda A, Kassa F. Microbial quality and safety of raw cow milk in Girar Jarso district of Oromia regional state, Ethiopia. Ethiopian Journal of Animal Production. 2019;19(1):37-55.

- Angela GR, Diaz AV, Lorenzo BH, et.al. Salmonella and Salmonellosis: An update on public health implications and control strategies. Animals. 2023;13(23):3666.

Crossref

© The Author(s) 2025. Open Access. This article is distributed under the terms of the Creative Commons Attribution 4.0 International License which permits unrestricted use, sharing, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.